In Part 2 of this 3 Part series I want to adress some of the issues and learnings I came across while printing the 26 wall panels.

After printing about 2,5kg of filament to develop the printing profile and finaly printing the wall panels I had to deal with following problem:

#1 Issue underextrusion

I checked the usual suspects when it comes to underestrusion:

- Printing temperature

- Printing speed

So I thought it is an missconfiguration in my cura profile, but no change of the profile result in better prints.

- Filament diameter / tension

I eliminated this as a cause, because I was able to print with this filament before.

- Clogged nozzle

I replaced the nozzle without a better result. Additionally I rekalibrated the printer and the extruder e-steps.

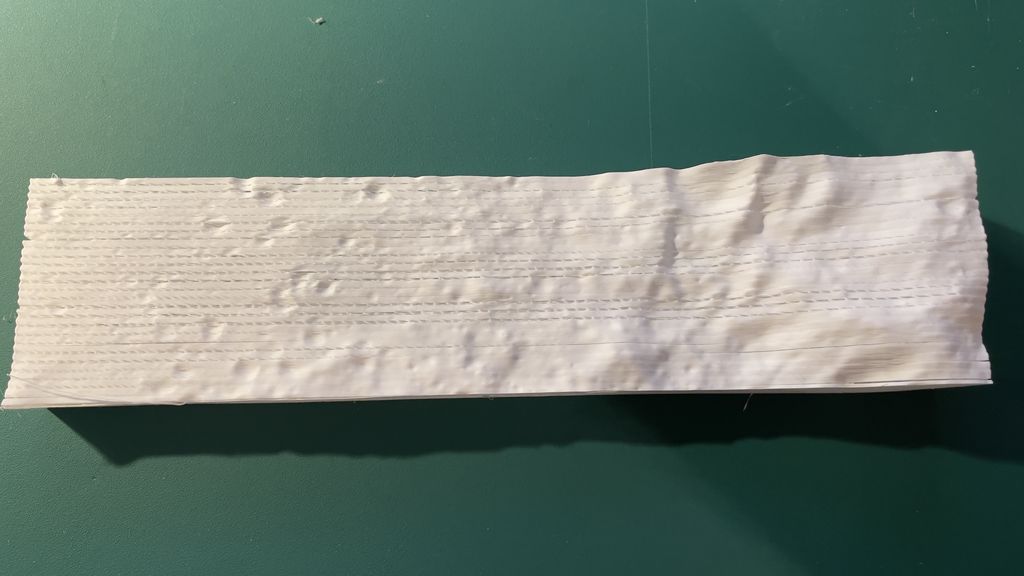

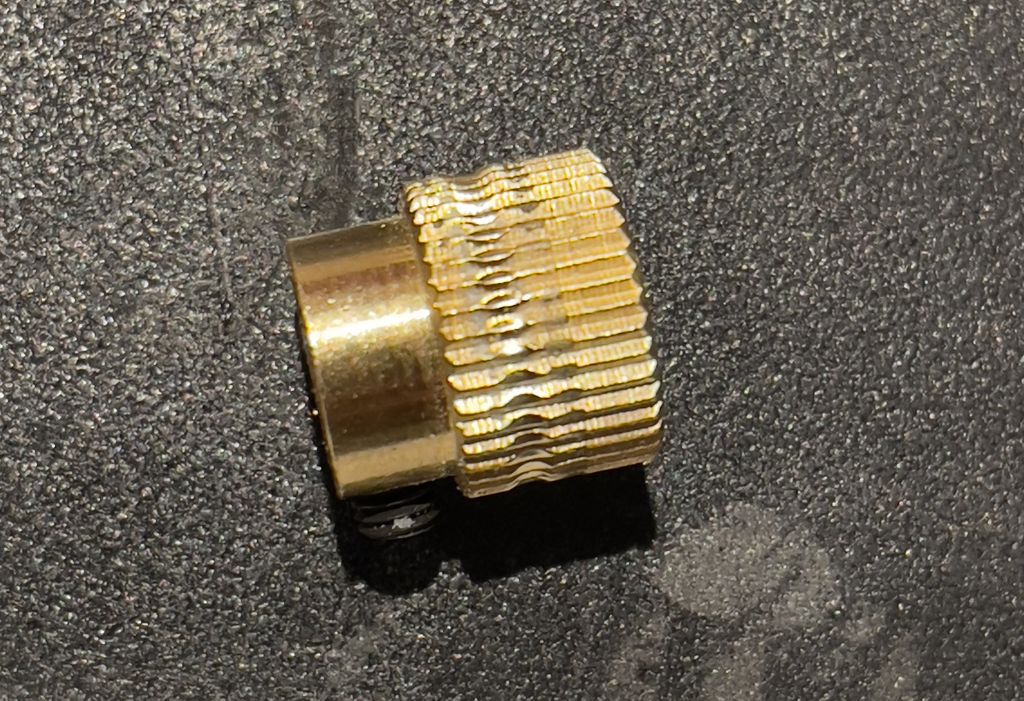

The last thing I checked was the extruder gear, because i could not think of a weardown of the wheel in this short time:

Obviously it was a misjudgement on my side 😅

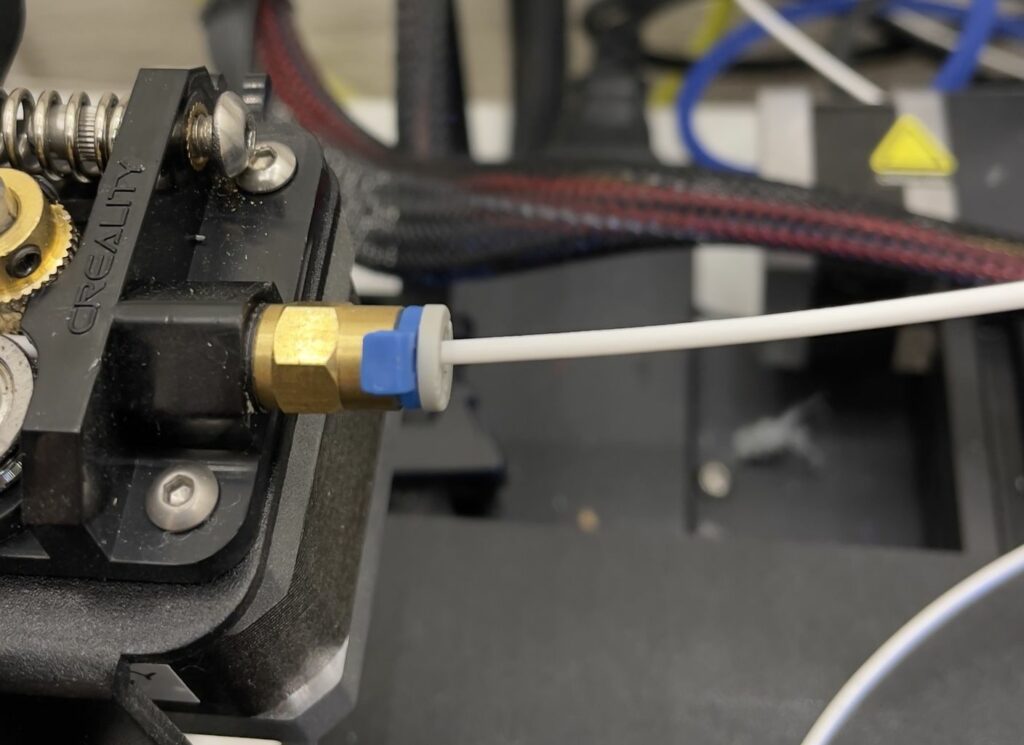

After replacing the extruder gear with a new one, I thought I could quickly print the remaining wall panel. Unfortunately the bowden tube slips out of the coupling. I was unable to keep it in place:

#2 Broken bowden tube coupling

It turns out that the bowden coupling was broken. Somwhere on redidt I found a way to quickly check if the coupling is broken. Remove the coupling from the extruder an the blue fix. When you press the grey coupling and there is no “klick” it is broken. So I replaced the coupling and was able to print the remaining five wall panels.

Schreibe einen Kommentar